Ensuring Quality from the First Part Produced

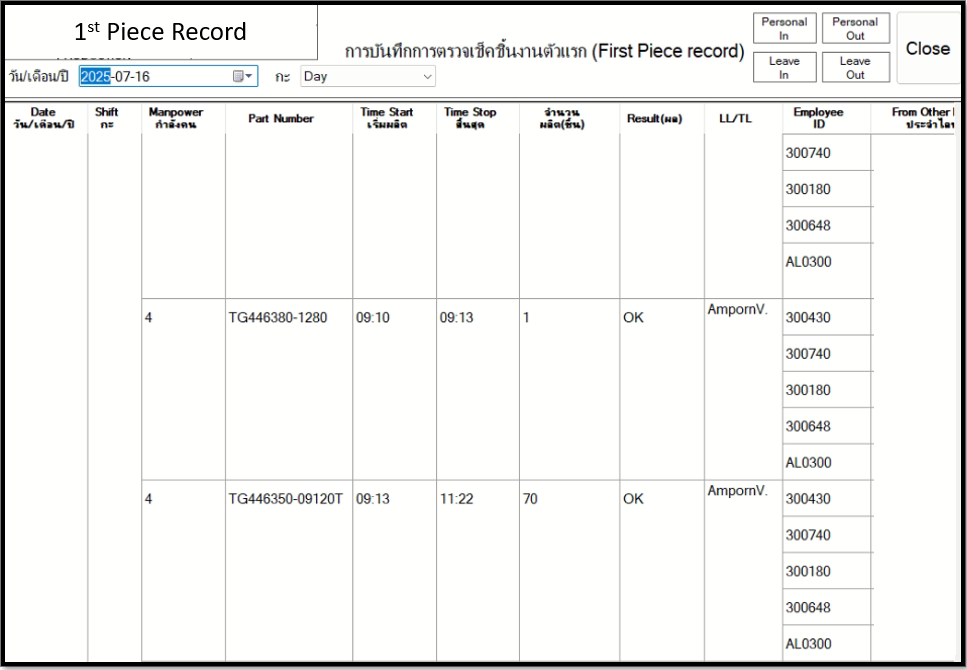

Our 1st Piece Record system provides a structured way to record and confirm every change of part number on the production line. Before mass production continues, the first piece must be checked, measured, and confirmed to meet all quality standards.

Key Features

First Piece Validation

Confirms product quality every time part numbers change.

Digital Traceability

Records operator, time, shift, and QC confirmation.

Real-Time Approval

Production continues only after first piece is confirmed.

Audit Ready

Standardized record format for compliance and customer requirements.

What We Do

Our 1st Piece Record system ensures every production changeover is properly verified and documented.

System Setup & Customization – Configure to match your production line, part numbers, and inspection workflow.

Integration with Production Line – Connect to operator terminals, scanners, and QC stations.

Inspection & Confirmation – Multi-level sign-off (Operator, QC, Supervisor) with digital records.

Reporting & Archive – Centralized database with dashboards, audit reports, and historical record retrieval.

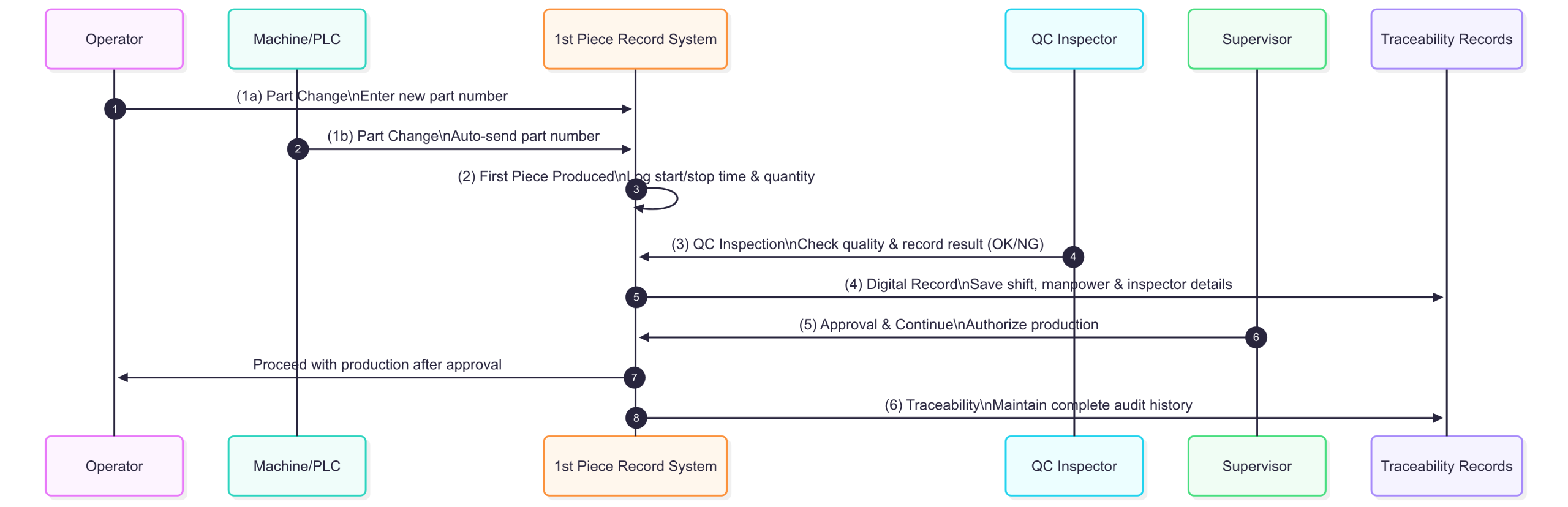

System Workflow

Part Change – New part number is registered either by operator input or automatically by machine signal.

First Piece Produced – The system logs start/stop time and production quantity.

QC Inspection – Inspector performs quality check and records the result (OK/NG).

Digital Record – System automatically saves shift, manpower, and inspector details.

Approval & Continue – Production can only proceed once the first piece is confirmed OK.

Traceability – A complete digital history is maintained for audits, compliance, and customer requirements.

Our 1st Piece Record software ensures every part change is validated through digital traceability, QC confirmation, and automated approval—delivering zero missed checks, reduced defects, and full audit compliance