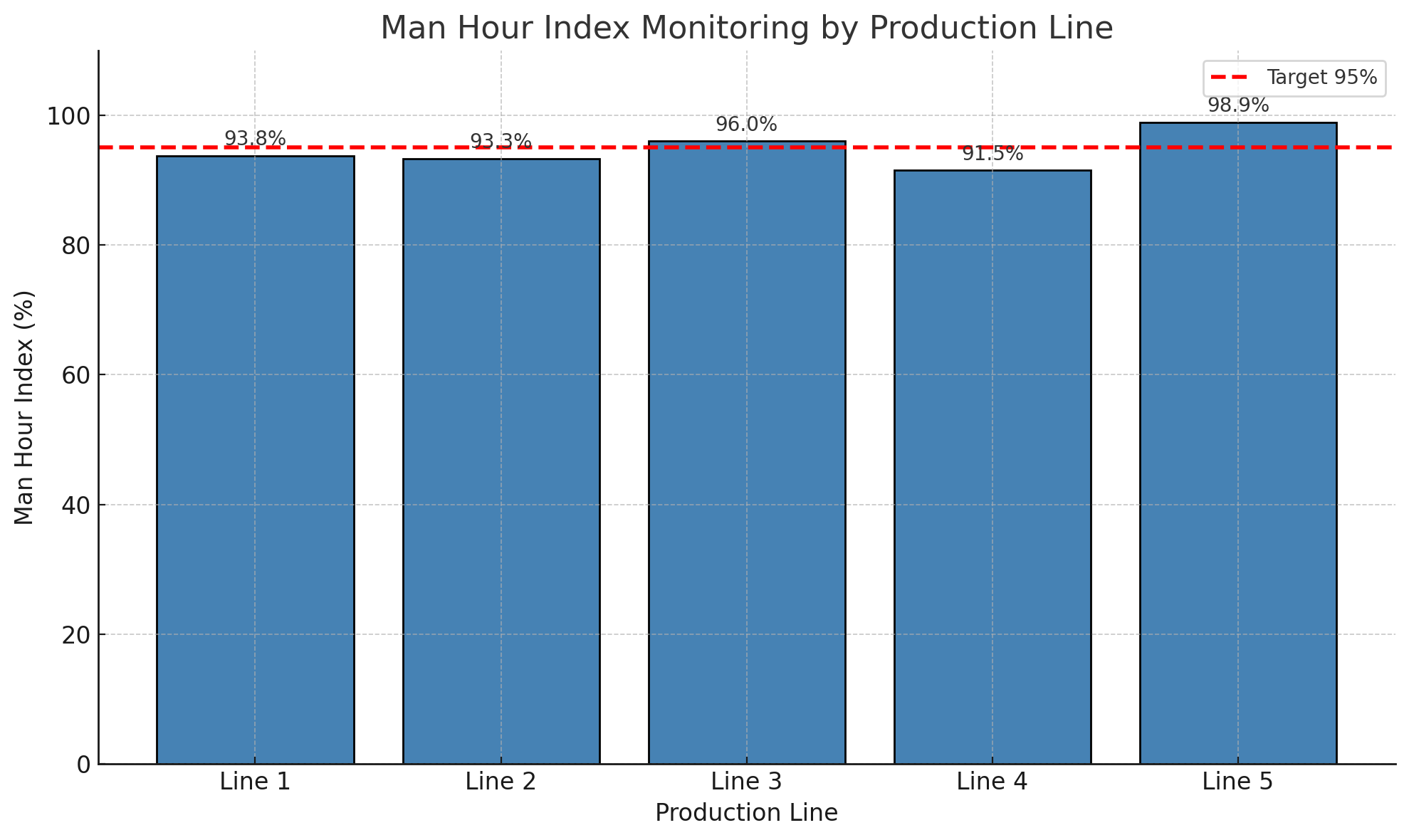

OEE — Overall Equipment Effectiveness

Workforce

Performance & Manpower Management

Optimize labor allocation. Maximize productivity. Ensure operational transparency.

Our Man-Hour Index software is designed to monitor and analyze employee working hours across each production line. The system provides real-time visibility into manpower deployment, helping supervisors ensure the right number of workers are assigned to the right place at the right time. With its integrated Manpower Map, you can instantly see where each operator is located and which task they are performing.

Key Features

RFID/Barcode Employee Check-In

Operators log in/out at workstations via RFID cards, barcode scanners, or biometric devices.

Workstation Assignment Tracking

Automatically records which line, process, or station each operator is working on.

Real-Time Manpower Map

Live dashboard view of all production lines with active headcount and employee IDs.

Performance Correlation

Links labor efficiency metrics to production output and quality KPIs.

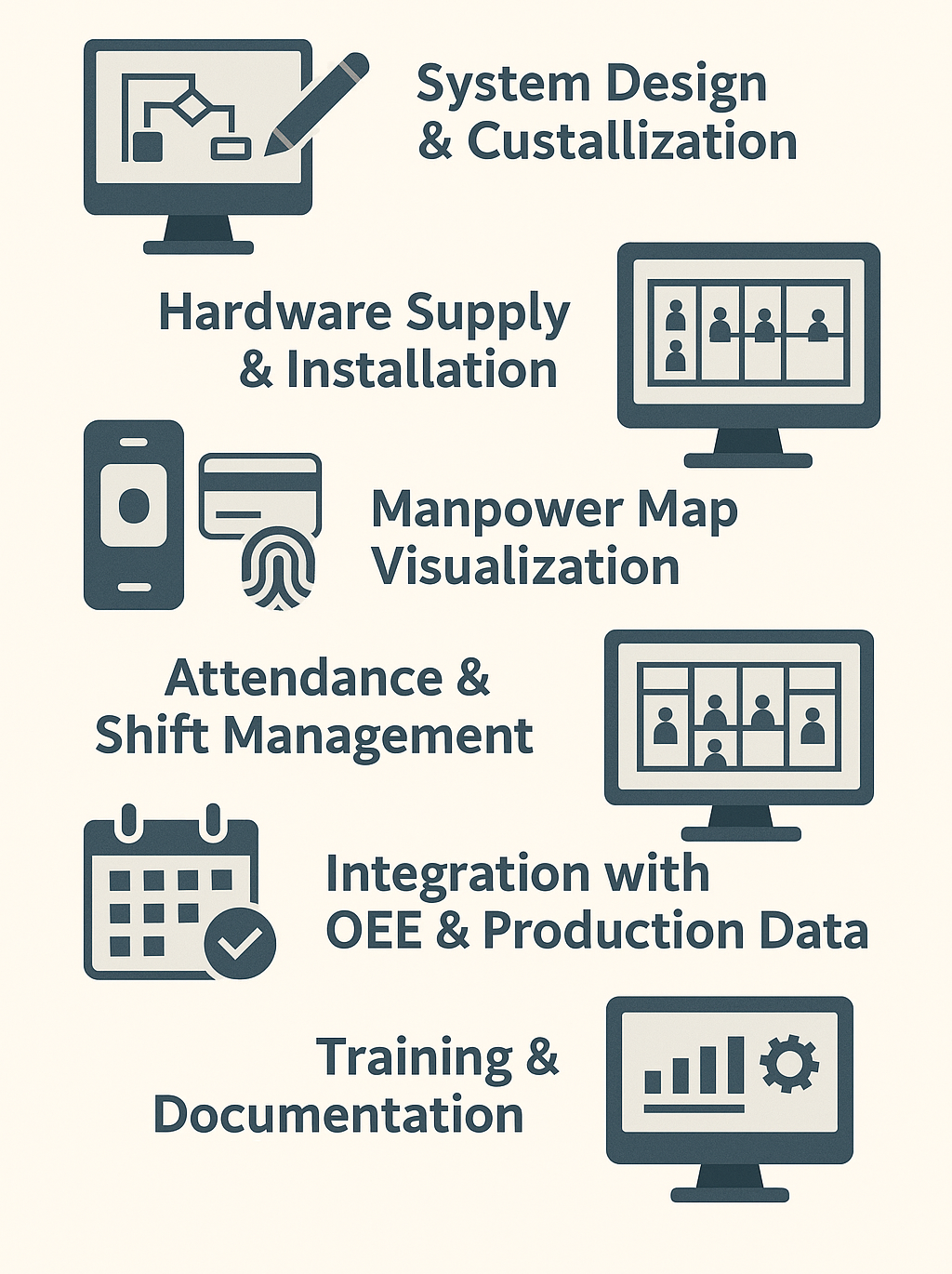

What We Do

System Design & Customization – Tailored configuration for your production line layout, manpower structure, and operational workflow.

Hardware Supply & Installation – Provision and installation of RFID readers, barcode scanners, biometric devices, and industrial PCs for operator check-in/check-out.

Manpower Map Visualization – Custom-designed graphical layouts showing live operator positions at stations, lines, or machines.

Attendance & Shift Management – Automated tracking of working hours, breaks, overtime, and absenteeism.

Data-Driven Labor Allocation – Real-time dashboards and reports for optimizing workforce distribution across lines and shifts.

Integration with OEE & Production Data – Linking labor efficiency directly with machine performance, quality output, and downtime records.

Training & Documentation – On-site operator/supervisor training, user manuals, and technical documentation.

After-Sales Support – Remote monitoring, troubleshooting, software updates, and feature upgrades.

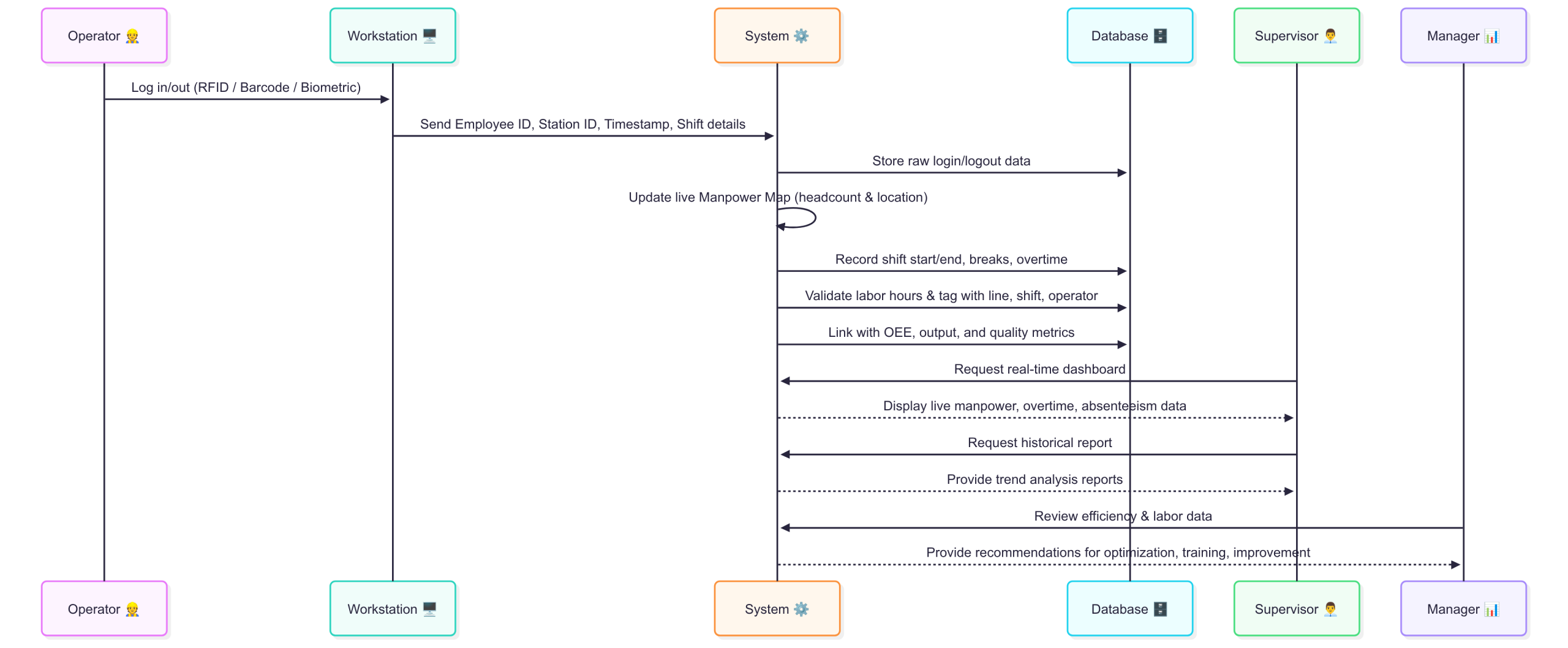

System Workflow

The Man-Hour Index system operates as a fully integrated workforce monitoring and management platform:

Employee Identification – Operators log in/out using RFID cards, barcode scanners, or biometric readers at their assigned workstation.

Data Acquisition – The system captures employee ID, station ID, timestamp, and shift details in real time.

Workstation Mapping – Collected data updates the Manpower Map, showing live headcount and operator locations per line or process.

Attendance & Shift Tracking – Automatically records shift start/end times, breaks, and overtime for each operator.

Data Processing – Labor hours are validated and stored in the central database, tagged with production line, shift, and operator details.

Performance Correlation – Workforce data is linked with OEE metrics, machine output, and quality data for efficiency analysis.

Visualization & Reporting – Supervisors access real-time dashboards and generate historical reports for manpower allocation, overtime usage, and absenteeism trends.

Decision Support – Managers use the data for labor optimization, training allocation, and continuous improvement initiatives.

Benefits

Real-Time Visibility – Instantly see labor efficiency for each line.

Quick Action – Reassign manpower before output is affected.

Cost Control – Reduce idle labor and overtime expenses.

Data-Driven Decisions – Use historical trends for workforce planning.

Performance Link – Correlate manpower with production output.

Audit Ready – Transparent, reportable labor utilization data.