Driving Efficiency Through Data-Driven Insights

Our OEE (Overall Equipment Effectiveness) solutions provide real-time visibility into your production performance, enabling you to detect inefficiencies, prevent downtime, and optimize resource utilization. Whether you operate a single line or a multi-factory network, our system delivers accurate, actionable insights for every shift, every day.

The system is powered by a centralized dashboard that consolidates all production lines into a single, switchable interface—providing a clear overview of factory performance at a glance.

Key Features

Real-Time Plan vs.

Actual Monitoring

Continuously tracks production output, comparing planned targets to actual results for each line to calculate OA% and identify performance gaps.

Automated Loss & Alarm Logging

Logs downtime events such as quality losses, machine breakdowns, and setup changes via barcode scanning or automatic PLC alarm code capture—eliminating manual data entry.

Centralized Multi-Line Dashboard

Combines all production lines into one switchable view, allowing rapid navigation between lines to view live status, downtime, and availability metrics.

DX-Ready Data Infrastructure

Uses Microsoft SQL Server as a stable, scalable database, enabling integration with Digital Transformation (DX) initiatives such as Man-Hour Index Reduction, Performance Analysis, First Piece Check, and the 3 Ten Set program.

What We Do

System Design & Engineering – Customized to your production line configuration and process flow.

Hardware Integration – PLCs, barcode scanners, operator panels, and industrial PCs.

Software Deployment – Centralized dashboards, reporting systems, and alert mechanisms.

Data Connectivity – OPC UA, Modbus TCP, EtherNet/IP, and database integration (SQL Server, PostgreSQL).

Training & Handover – On-site commissioning, operator training, and detailed technical documentation.

After-Sales Support – Remote monitoring, troubleshooting, and system upgrades.

System Workflow

The Production Performance system operates as a fully integrated monitoring and control platform—capturing, processing, and reporting production data in real time to ensure transparency, accuracy, and rapid decision-making.

1. Data Acquisition

Production lines send live output data, downtime events, and machine status information directly from barcode scanners, PLCs, and manual operator inputs to the central SQL database.

2. Data Processing

The system validates, categorizes, and timestamps all incoming records, applying shift and line identifiers for accurate tracking.

3. Visualization

A centralized dashboard displays Plan vs. Actual output, OEE%, loss time by category, and alarm history for all lines, with the ability to switch between detailed line views.

4. Loss Logging

Downtime causes (quality loss, machine breakdown, setup change, etc.) are logged automatically from PLC alarms or via operator scans, ensuring complete and accurate loss time records.

5. Performance Evaluation

OEE% and other performance metrics are calculated in real time, enabling immediate detection of deviations from targets.

6. DX Integration

Stored data is available for advanced Digital Transformation initiatives such as Man-Hour Index analysis, performance trend reporting, and predictive maintenance planning.

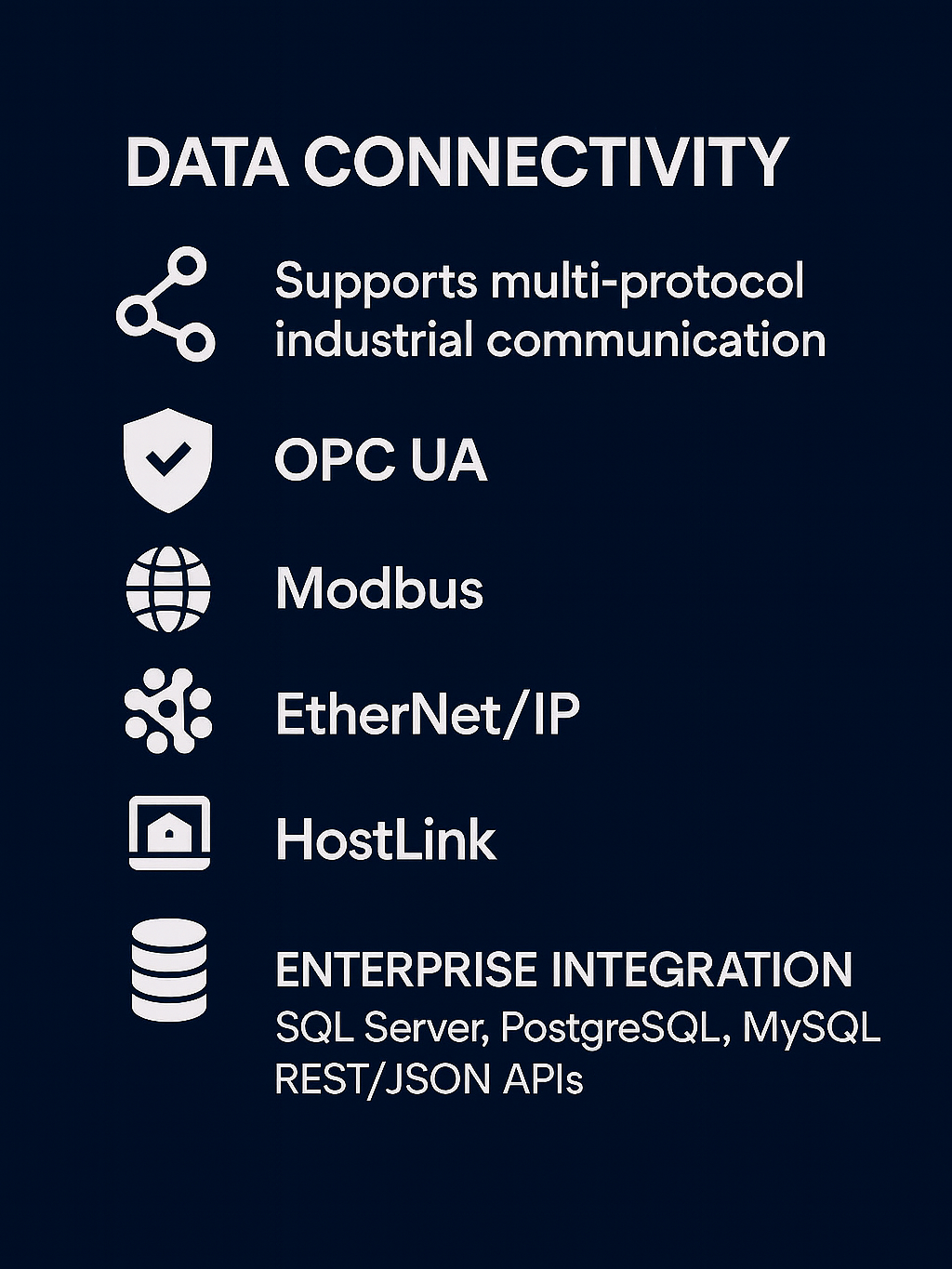

Data Connectivity

Supports multi-protocol industrial communication including:

OPC UA – Secure, platform-independent data exchange for industrial automation.

Modbus TCP/RTU – Widely adopted protocol for machine-to-machine communication.

EtherNet/IP – High-speed, real-time communication for industrial control networks.

HostLink (Omron) – Direct serial/ethernet communication with Omron PLCs.

MC Protocol (Mitsubishi) – Native protocol for Mitsubishi PLC data exchange.

PLC Compatibility:

Siemens S7

Mitsubishi Q/R/FX Series

Omron CJ/CP/NX Series

Allen-Bradley ControlLogix / CompactLogix

Keyence KV Series

Enterprise Integration:

SQL Server, PostgreSQL, MySQL

REST/JSON APIs for MES, ERP, and cloud analytics platforms

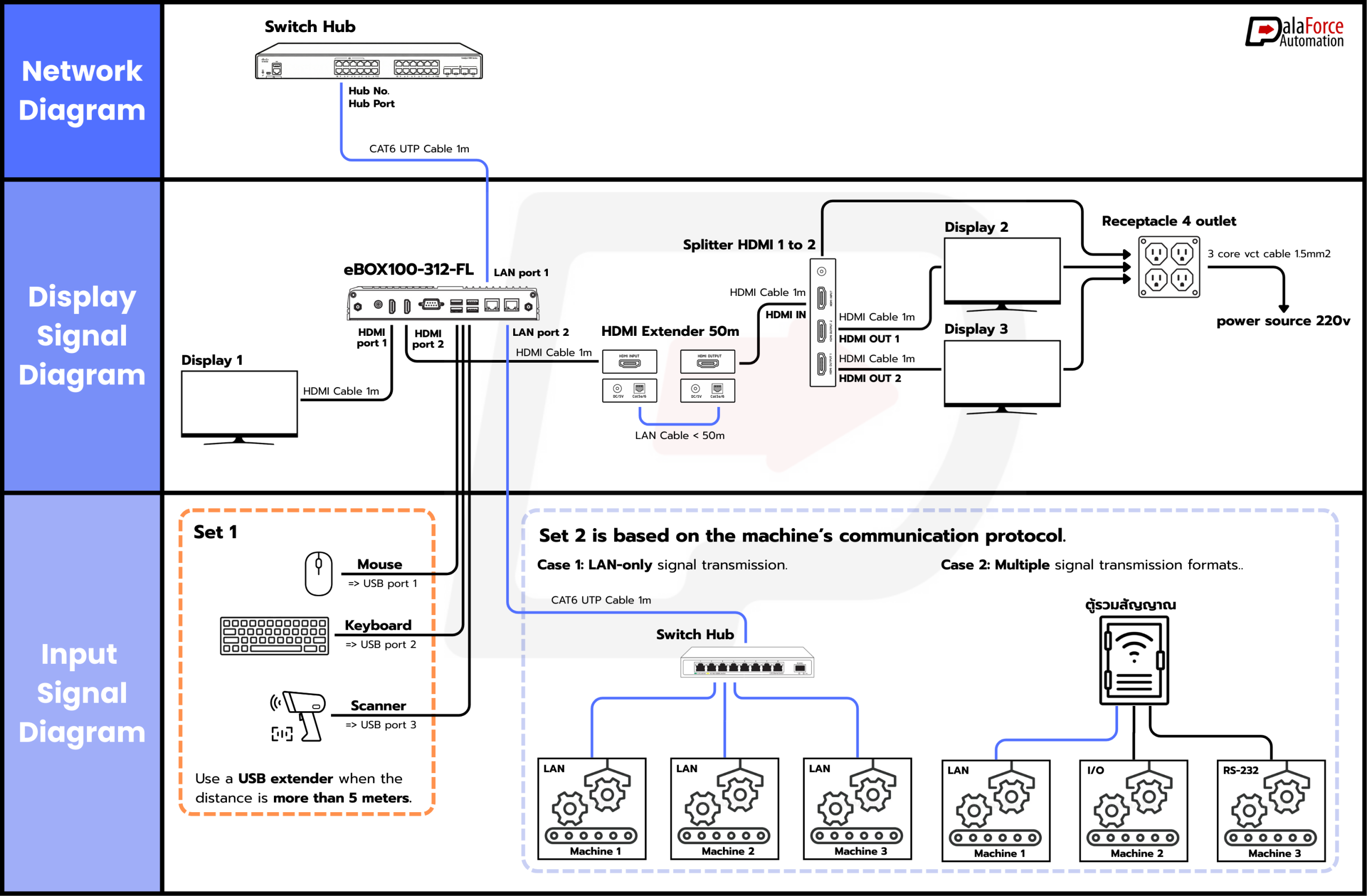

OEE Hardware Diagram

The diagrams help users understand how machine signals, network components, and display interfaces work together to deliver real-time OEE monitoring.

The system overview is divided into three key diagram types: