OEE — Overall Equipment Effectiveness

DX Transformation From Paper to Digital

Traditional Standardized Work Sheets (SWS) on paper are often outdated, hard to retrieve, and prone to human error.

Our Real-Time Standardized Work software eliminates paper forms by digitizing, mapping, and auto-displaying Standardized Work PDFs in sync with production line part changes.

Key Features

Paperless Standardization

Replace outdated paper forms with live, digital Standardized Work Sheets that are always up to date.

Auto-Sync with Production Line

Instantly display the correct work PDF as part numbers change on the line—no manual searching required.

Error Reduction & Compliance

Minimize human error while ensuring every operator follows the latest approved work instructions.

Fast Access & Traceability

Securely store and retrieve all Standardized Work documents anytime, with full visibility across the production floor.

What We Do

We deliver a paper-to-digital Standardized Work platform that integrates seamlessly with your production control system.

Our scope of supply includes:

Part Number Database Mapping – Assign Standardized Work to product SKUs in a secure database.

System Integration – Connect with PLCs, MES, or ERP to detect part number changes in real time.

Operator Interface – Provide a simple terminal view showing the correct Standardized Work instructions.

Change Management – Centralized upload/update of new Standardized Work with version tracking.

Training & Support – Operator training, documentation, and long-term system maintenance.

Touchscreen Hardware & Program Supply – Deliver and configure industrial-grade computers with touch displays, pre-installed with the Standardized Work software.

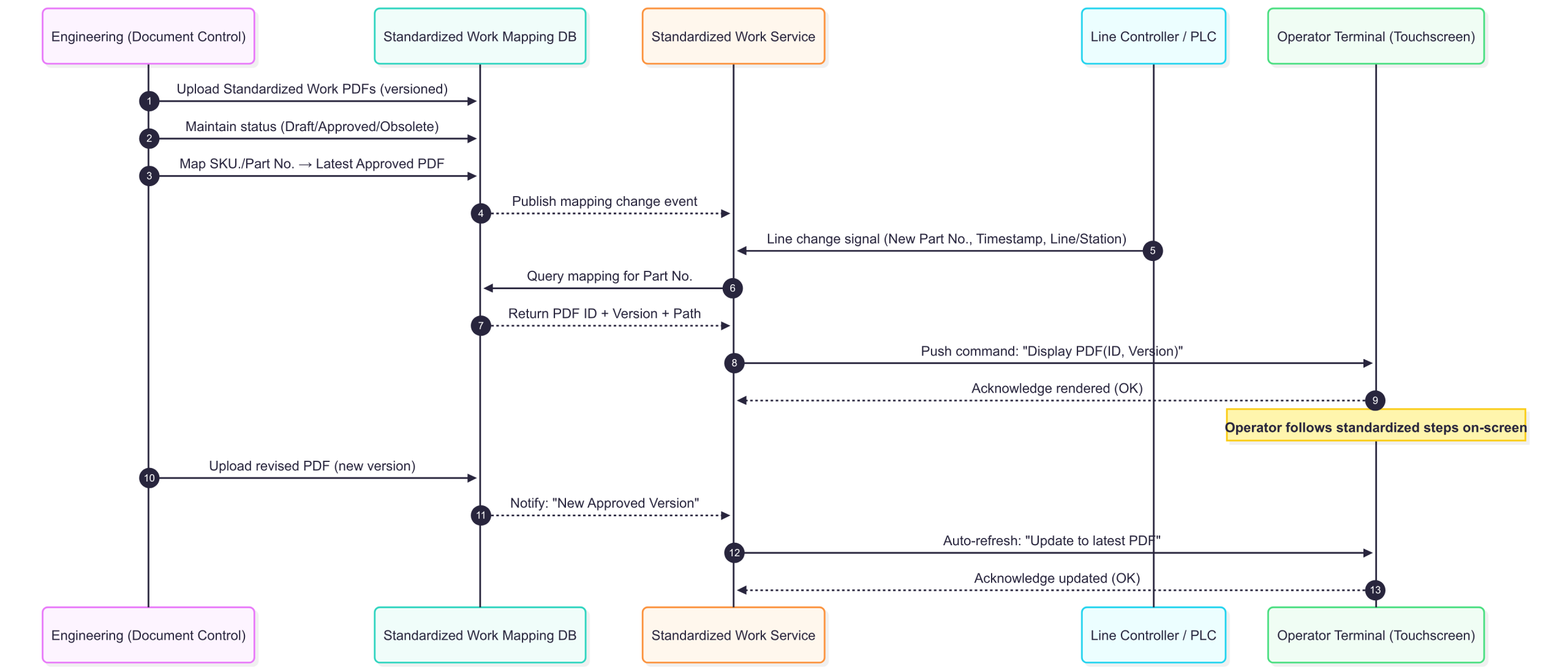

System Workflow

Document Control – Upload Standardized Work PDFs to central repository with version control.

Part Number Mapping – Link each SKU/part number with its corresponding PDF.

Production Line Change – When a new part number is selected at the line, the system detects the change.

Auto Display – The correct Standardized Work PDF appears on the operator’s screen immediately.

Operator Execution – Workers follow the standardized method shown digitally.

Continuous Updates – When engineering updates a work method, the new PDF is automatically pushed to all terminals.