End-to-end part genealogy with real-time verification and process interlocks.

Our Traceability System captures identifiers and process data from multiple sources—barcode, QR code, 2D code readers (auto-trigger), PLCs, and machine controllers—then stores, verifies, and links each event in a central database. The platform enforces interlocks to prevent the next process step unless rules are passed, and supports call-back checks to re-verify lots or parts against customer or internal requirements.

Key Features

Multi-Source Data Capture

Barcode, QR code, PLC, machine signals, and 2D code readers with auto-trigger capability.

Real-Time Verification

Validate routing, revision, expiry, duplicates, and quality gates before allowing the next process step.

Process Interlocks

Automatic PLC/machine interlocks to stop production until criteria are passed, with supervisor override options.

Call-Back & Genealogy

Complete trace history, recall management, and genealogy linking from raw material to finished goods.

What We Do

System Integration – Connect scanners, PLCs, machines, and operator terminals into a unified traceability database.

Automatic Triggering – Configure 2D code readers to fire on events from PLC or sensors, eliminating manual scanning delays.

Database & Genealogy – Store all captured data (part numbers, lots, operators, parameters) with full genealogy mapping.

Verification & Control – Enforce routing, recipe, and expiry rules, applying hard/soft interlocks to ensure process compliance.

Call-Back Mechanism – Support product recalls, supplier issues with automatic quarantine and re-verification.

Reporting & Dashboards – Provide genealogy searches, verification failure analysis, and compliance-ready reports.

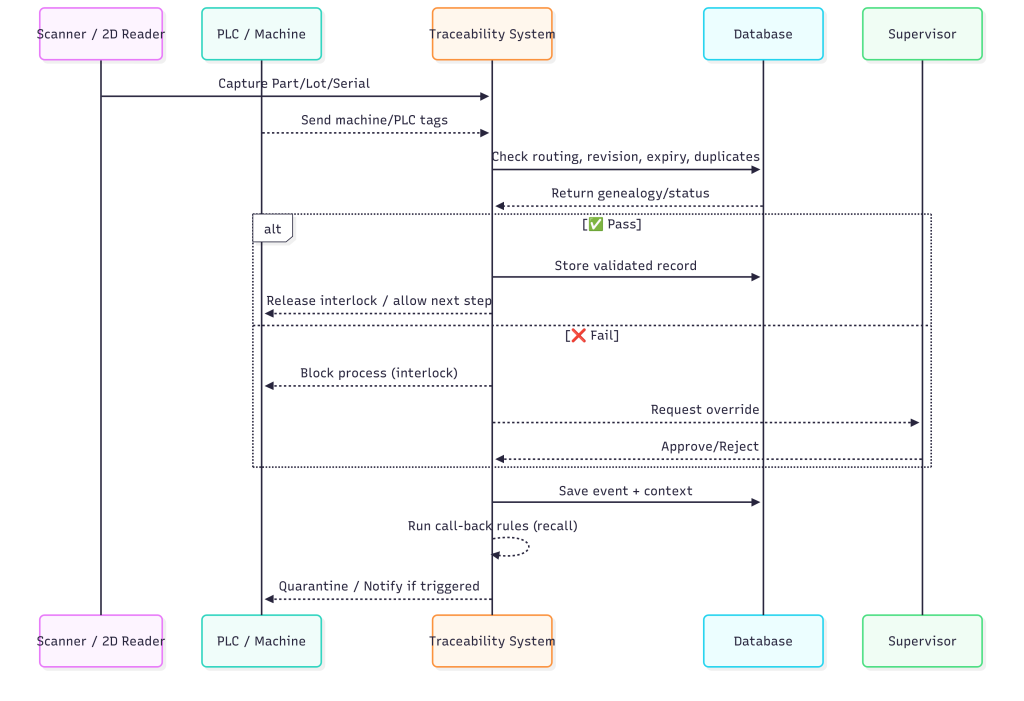

System Workflow

Scan / Auto-Trigger – Barcode, QR, or 2D code reader captures serial/lot information automatically.

Data Acquisition – System pulls machine/PLC tags and operator inputs alongside the scanned data.

Verification – Checks routing, revision, expiry, and duplication rules in real-time.

Decision Point

✅ Pass → Store data in the database, release PLC interlock, and allow next process step.

❌ Fail → Block next step, highlight error, require supervisor override or re-scan.

Storage – Write validated data into central traceability database with operator, shift, machine, and timestamp.

Trace & Call-Back – Provide genealogy search, call-back actions (quarantine, re-inspection), and compliance reporting.

Tech Specs

- Industrial Protocols – OPC UA, Modbus TCP/RTU, EtherNet/IP, Mitsubishi MC Protocol, and Omron HostLink for seamless PLC and machine integration.

- Databases – Compatible with Microsoft SQL Server and PostgreSQL for enterprise-grade storage and query performance.

- APIs & Integration – REST/JSON APIs for MES/ERP connectivity; webhook-based alerts for Microsoft Teams, email, or third-party systems.

- Performance – Sub-second response time at the station level (typically <300 ms with local caching).

- Deployment Options – Flexible architecture supporting on-premise Windows servers or hybrid edge with centralized database infrastructure.

- Audit & Security – Immutable audit trail with UTC timestamps, device signatures, and role-based access controls to ensure compliance and traceability.